Tinplate and Tin Free Steel

Tinplate and Tin Free Steel

Tin mill products include electrolytic tinplate, electrolytic chromium coated steel (also referred to as tin free steel or TFS), and black plate, the uncoated steel. Tinplate is a thin steel sheet coated by tin, while TFS is an electrolytic chrome plated steel consisting of a thin layer of chromium and a layer of chromium oxide deposited on the steel base. Both of them have a beautiful, metallic luster as well as excellent properties in corrosion resistance and paintability.

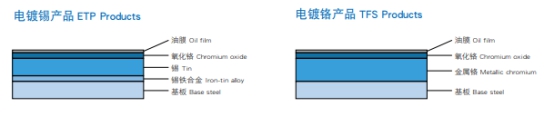

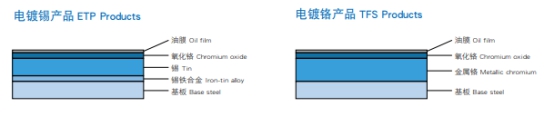

Coating Structure

Features of Tinplate Products

Excellent Corrosion Resistance:

By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents.

Excellent Paintability & Printability:

Printing is beautifully finished using various lacquers and inks. Excellent Solderability & Weldability TIN PLATE is widely used for making various types of cans by soldering or welding.

Excellent Formability & Strength:

By selecting a proper temper grade, appropriate formability is obtained for various applications as well as the required strength after forming.

Beautiful Appearance:

Electrolytic ETP is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Features of TFS Products

Excellent paint adhesion:

TFS has excellent paint adhesion properties that far surpass those of ETP, allowing its use for making DRD cans and adhesive bonded cans.

Excellent heat resistance:

High-temperature baking causes neither discoloration nor deterioration in material properties.

Excellent resistance to Sulphur Blackening:

The metallic chromium in TFS has excellent sulphide resistance property when canning protein-rich foodstuff such as fish. TFS compensates for the expensive sulphur resistant lacquer.

Excellent filiform rust resistance:

TFS has a excellent under film corrosion resistance.

Excellent alkali resistance:

The coating in TFS is not amphoteric. Alkaline products such as detergents and dispersion colours can be packed in TFS with advantage.

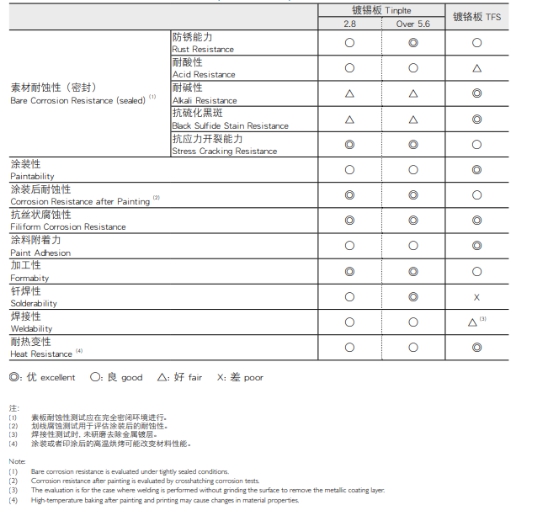

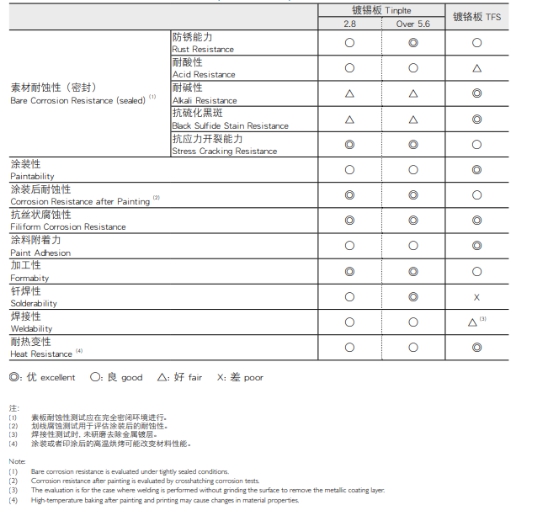

Comparison of Properties

Tin mill products include electrolytic tinplate, electrolytic chromium coated steel (also referred to as tin free steel or TFS), and black plate, the uncoated steel. Tinplate is a thin steel sheet coated by tin, while TFS is an electrolytic chrome plated steel consisting of a thin layer of chromium and a layer of chromium oxide deposited on the steel base. Both of them have a beautiful, metallic luster as well as excellent properties in corrosion resistance and paintability.

Coating Structure

Features of Tinplate Products

Excellent Corrosion Resistance:

By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents.

Excellent Paintability & Printability:

Printing is beautifully finished using various lacquers and inks. Excellent Solderability & Weldability TIN PLATE is widely used for making various types of cans by soldering or welding.

Excellent Formability & Strength:

By selecting a proper temper grade, appropriate formability is obtained for various applications as well as the required strength after forming.

Beautiful Appearance:

Electrolytic ETP is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Features of TFS Products

Excellent paint adhesion:

TFS has excellent paint adhesion properties that far surpass those of ETP, allowing its use for making DRD cans and adhesive bonded cans.

Excellent heat resistance:

High-temperature baking causes neither discoloration nor deterioration in material properties.

Excellent resistance to Sulphur Blackening:

The metallic chromium in TFS has excellent sulphide resistance property when canning protein-rich foodstuff such as fish. TFS compensates for the expensive sulphur resistant lacquer.

Excellent filiform rust resistance:

TFS has a excellent under film corrosion resistance.

Excellent alkali resistance:

The coating in TFS is not amphoteric. Alkaline products such as detergents and dispersion colours can be packed in TFS with advantage.

Comparison of Properties