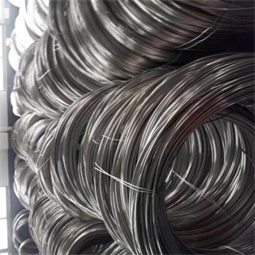

Galvanized Iron Wire

Galvanized Iron Wire

Galvanized iron wire production process,using high quality low carbon steel wire after drawing molding, acid pickling, annealing, galvanizing cooling process processing.Galvanized iron wire with good toughness and flexibility, the highest amount of zinc can reach 300 grams / square meter. With galvanized coating thickness, strong corrosion resistance and other characteristics.

Common galvanized wire for hot dip galvanized wire and cold galvanized wire, galvanized wire) distinction: hot dip galvanizing is dipped in melted liquid zinc, fast production, coating thickness but not uniform, the market allows the minimum thickness 45 microns, up to a maximum of more than 300 microns. Color is dark, consumption of zinc metal, metal matrix and the form of infiltrated layer, good corrosion resistance, outdoor environment galvanized can be maintained for several decades.Galvanized iron wire is widely used in the industrial fields and the daily lives. It can be as the basic material of many meshes, like weld wire mesh, crimped wire mesh, diamond mesh, hexagonal wire netting, hardwire cloth, slope protect wire mesh, gabion box, filter screen, mine screen mesh, chain link fence, fence netting etc.

It also used in other fields like galvanized wire mesh fenceing for the protection of agricultural and commercial properties; used in various automotive components; communication equivaments; packaging products; manufacture of galvanized barbed wire; galvanized wire rope of low and high strength; used in medical components etc.

Galvanized iron wire mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.EastasiaMetal is a professional manufacturer and global exporter specializing in metal manufacture and exportation since 1998.